Using numerical control shearing machine for net size blanking this is specially applied in piece processing with lower demand most of the process engineer use shearing machine for blanking to reduce the processing cost.

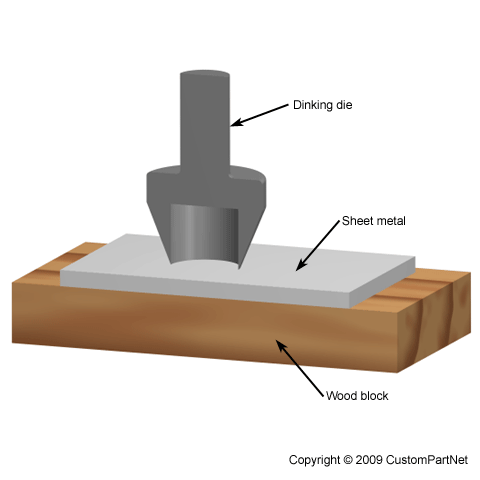

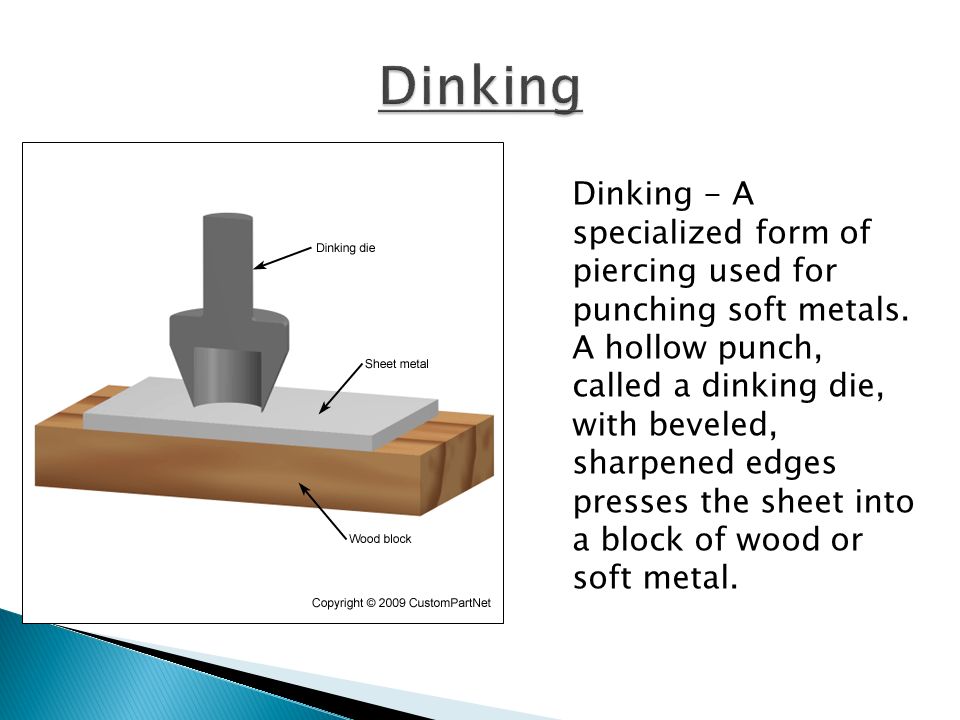

Dinking process in sheet metal.

The die located underneath the sheet has a cutout in the shape of the desired feature.

Metal spinning process duration.

Dot dinking tools duration.

The punching process requires a punch press sheet metal stock punch and die.

Dinking die set up in semi automatic machine mark reid.

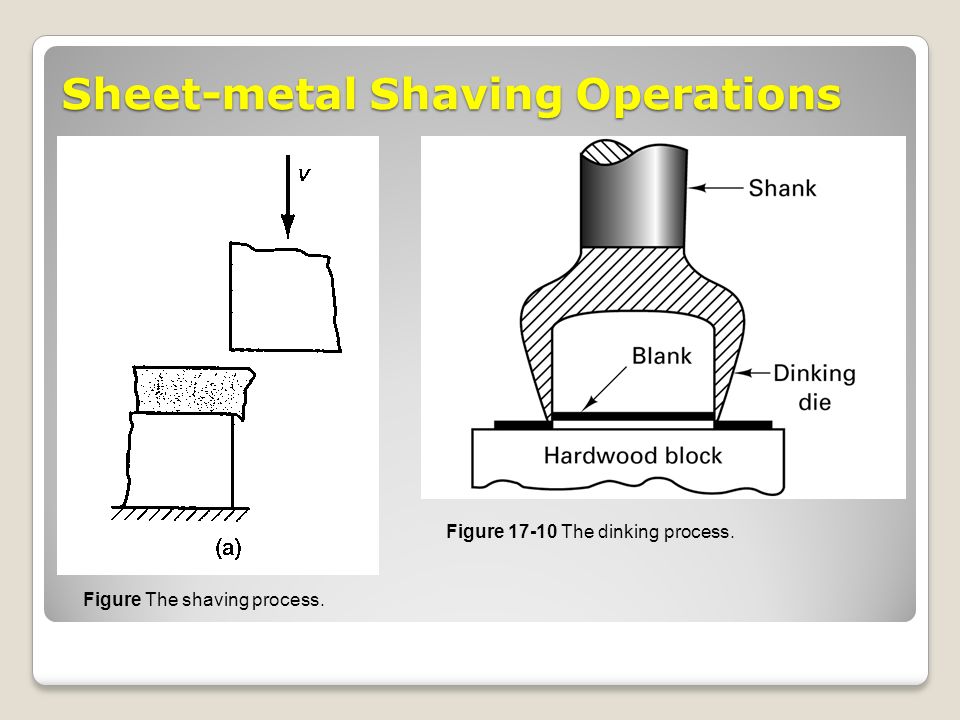

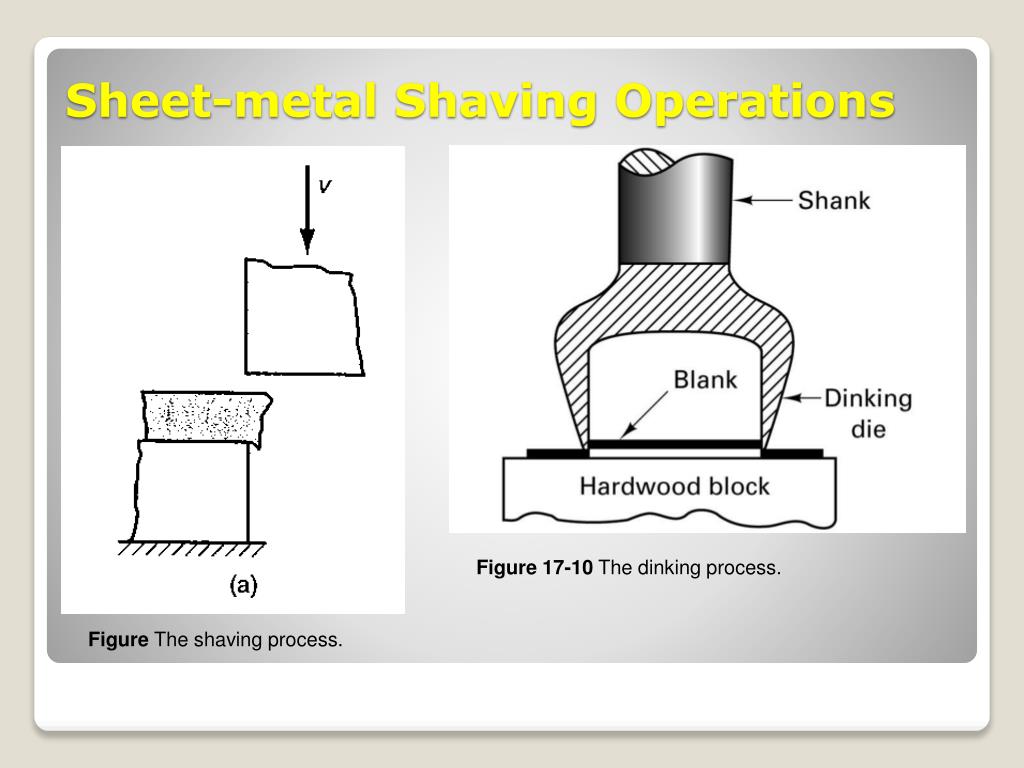

Shearing process using a die and punch where the exterior portion of the shearing operation is to be discarded.

The process of getting rectangular workpiece by shearing machine.

Sheet metal operations.

Metal spinning process duration.

We pick up your unwanted aluminum copper brass and recycle other metal as well.

In the metalworking and leather industries the process is known as clicking and the machine may be referred to as a clicking machine.

Shearing process using a die and punch where the interior portion of the sheared sheet is to be discarded.

Most of these products have metal casings that are made by cutting and bending sheet metal.

Let us dispose of your junk automobile even if it does not run.

This allows for complex shapes to be formed in sheet metal up to 6 mm 0 25 in thick using simple tools.

Sheet metal processing terminology 1 10.

Mark reid 844 views.

3 that is essentially a small punch and die that reciprocates quickly.

The sheet metal stock is positioned between the punch and die inside the punch press.

The nibbling process cuts a contour by producing a series of overlapping slits or notches.

Sheet metal operations operations performed on sheet metals sheet metal processes.

Shearing the sheet into two or more pieces.

Punching a number of holes in a sheet 4.

Everyday hauling is your first choice for metal recycling hauling moving and clean up.

When the blanking of sheet metal process the removal of piece is called as blank.

Around 300 900 times per minute.

Sheet metal processing is an important process for many industries producing home appliances fridge washer dryer vacuum cleaners etc electronics dvd and cd players stereos radios amplifiers etc toys and pc s.

Die cutting is the general process of using a die to shear webs of low strength materials such as rubber fibre foil cloth paper corrugated fibreboard chipboard paperboard plastics pressure sensitive adhesive tapes foam and sheet metal.

The sheet metal blanking process is a one of the shearing operation.